Cryogenic provides tailored solutions for the safe and precise loading and unloading of tank trucks and railcars through our customized skid systems.

These one-stop solutions are designed to meet the specific needs of the Oil & Gas, Petrochemical, and Chemical industries, adhering to the latest industry standards and local regulations.

1. Customized Design:

Our loading skid systems are custom-designed based on the unique process parameters and controlling philosophy specified by each client. This ensures a solution that perfectly aligns with the operational requirements of the facility.

2. Top or Bottom Loading/Unloading:

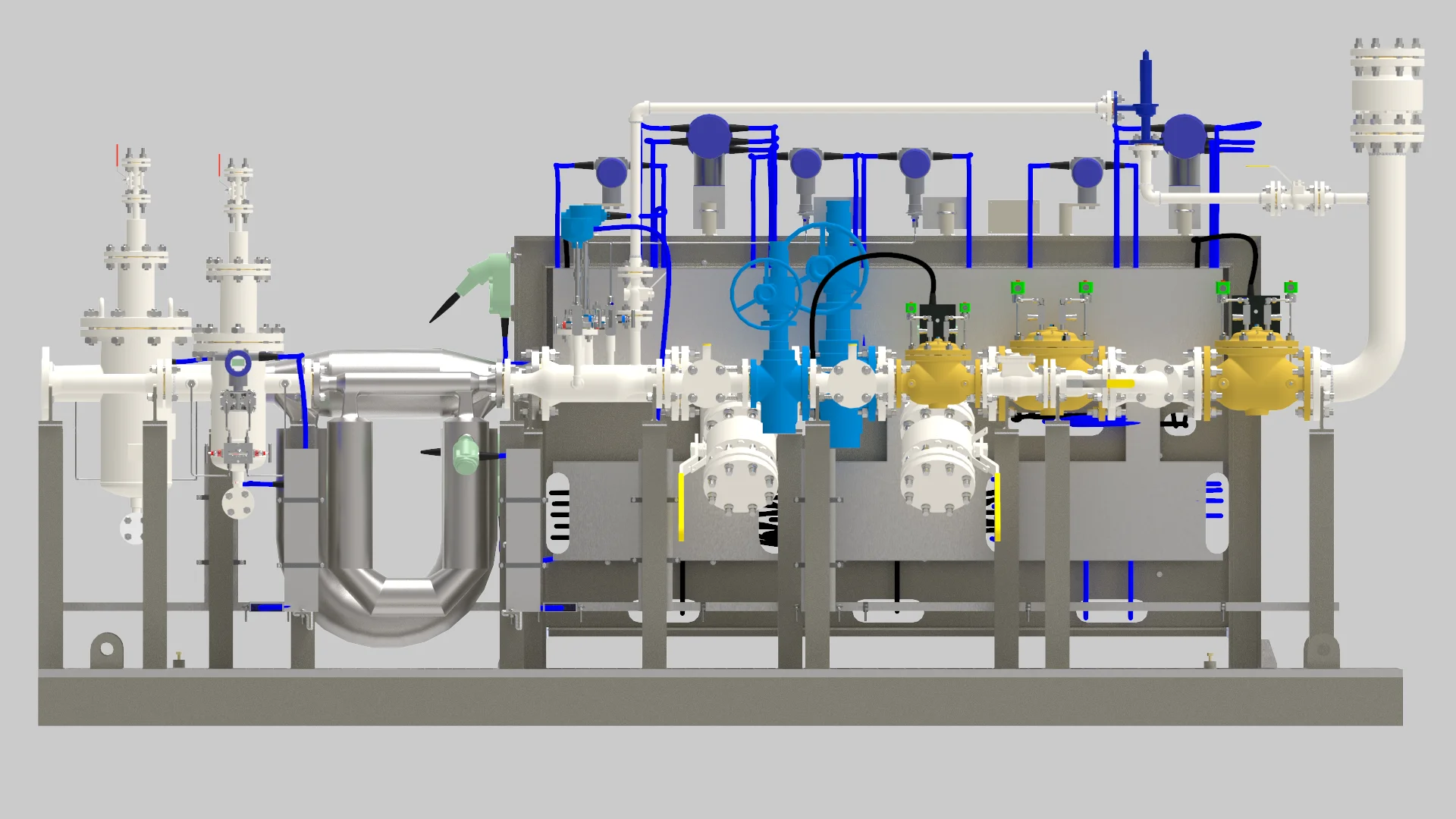

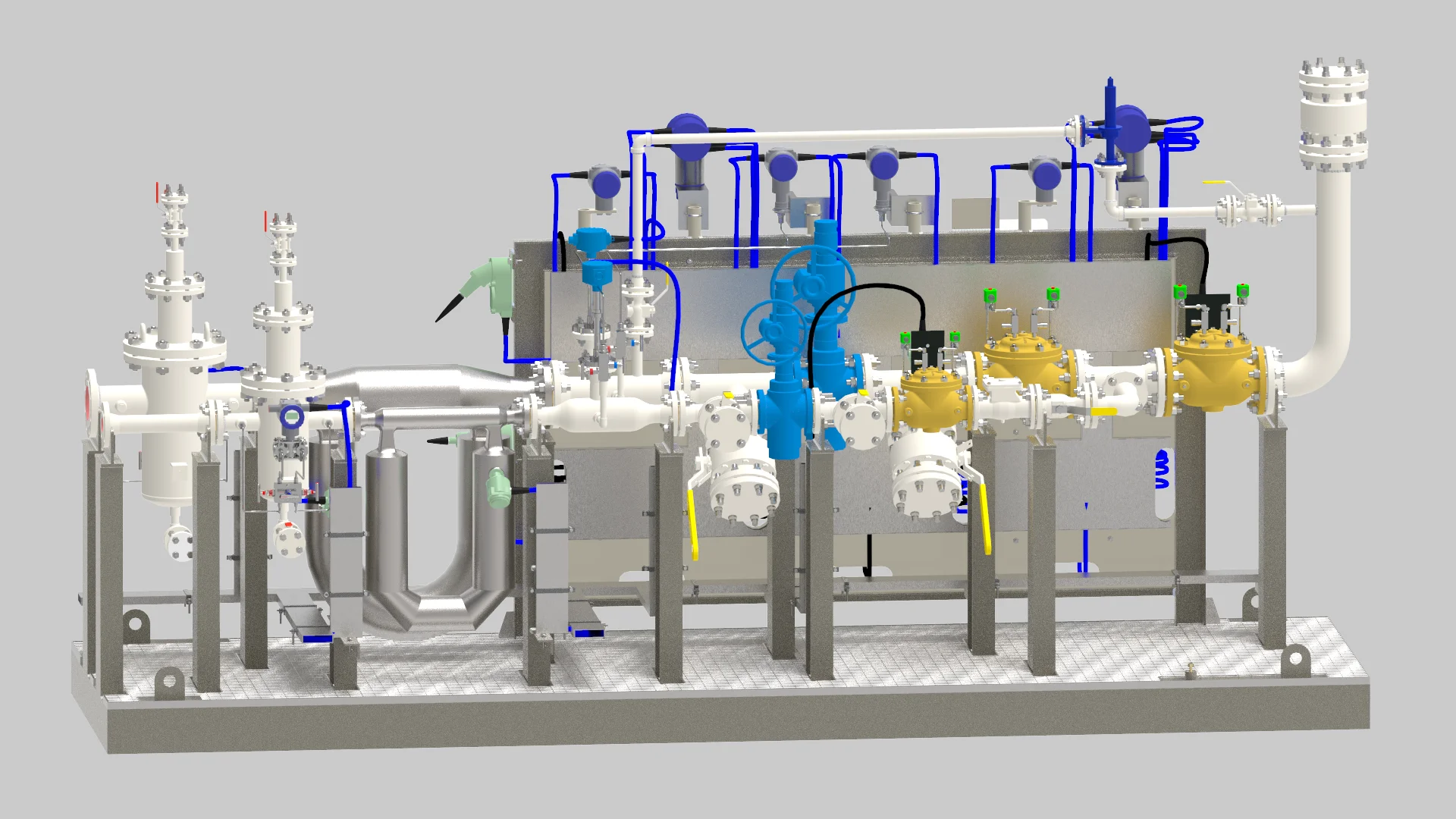

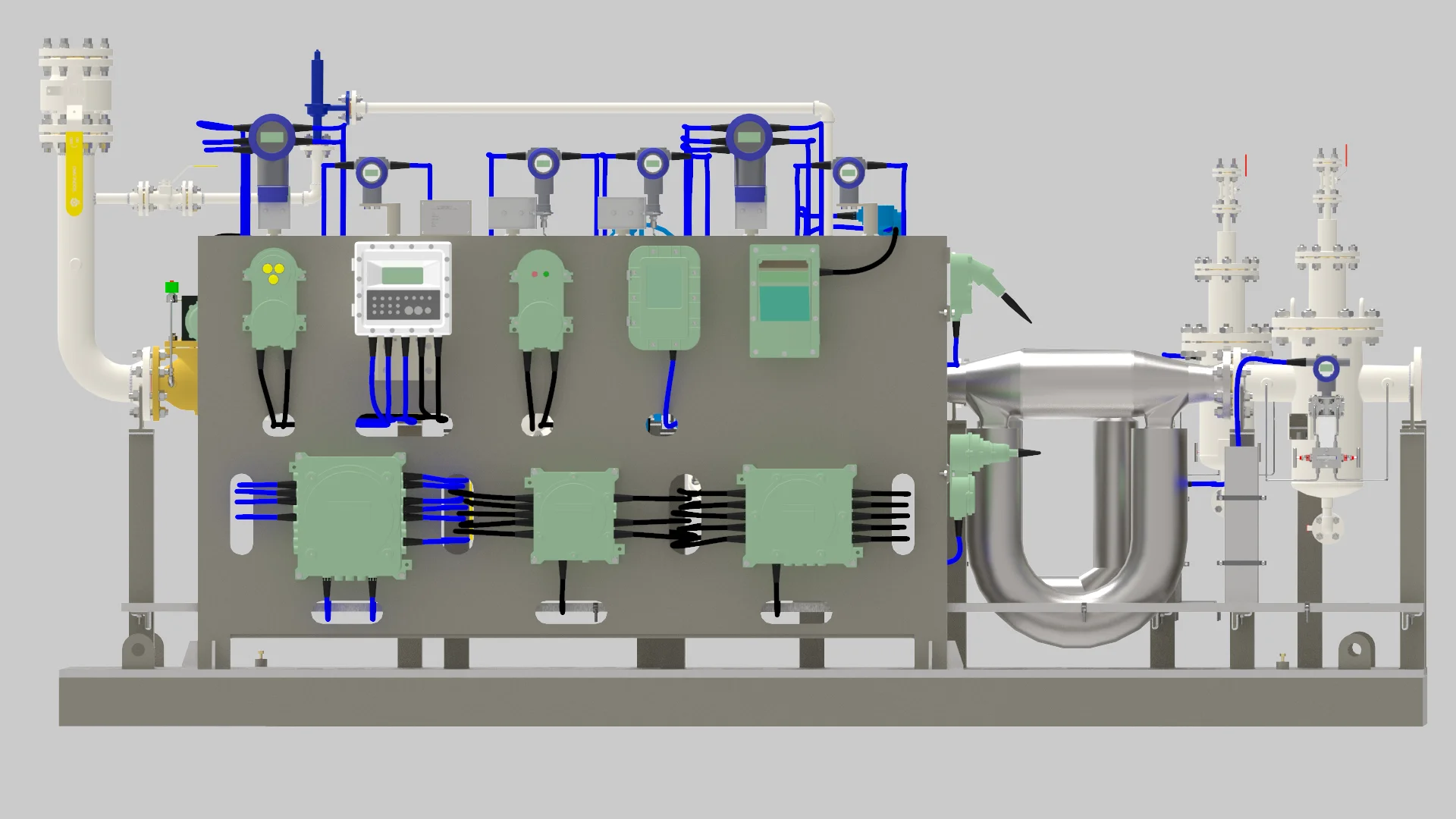

The fully integrated loading skid packages are designed to suit both top and bottom loading/unloading scenarios. These packages include loading arms, flow meters (PD, Coriolis, or Turbine based on process requirements), batch controlling systems, instrumentation, and associated piping, electrical, and structural steel components.

3. LPG Loading System:

Catering to the Oil & Gas Industry, our loading skids for LPG (liquefied petroleum gas) adhere to API Chapter 6.2/API RP1004/API RP 2003 standards. They cover a flow capacity range of 20 m3/hr to 150 m3/hr , with sizes ranging from 2" to 4". These skid systems can handle services like Gasoline, Diesel, Kerosene, Jet Fuel, White oil, Naphtha, Benzene, Condensate, Slop oil, etc. Additional features such as additive injection, odorant injection, and blending options are available.

4. Materials and Capacities:

Skid systems are manufactured in various materials, including carbon steel, low-temperature carbon steel, and stainless steel grades. Capacities range from typical sizes of 2" to 4". We handle critical applications such as Molten Sulphur, Bitumen, Phenol, Sulphuric Acid, Toluene, where skid design, integration of steam/electrical heat tracing system, hot insulation, and purging systems play a crucial role in efficient and safe operation.

5. Safety Certifications:

Our skid systems meet end-user and local statutory requirements for hazardous area certifications, including FM/UL/CSA/ATEX/IEC, ensuring compliance with international safety standards.

6. Plug and Play System:

In-house fabrication, assembly, and system integration on a single frame make our skid systems a plug-and-play solution, minimizing on-site work and ensuring efficient installation.

7. Ease of Maintenance and Accessibility:

Cryogenic's loading skid systems are designed for ease of maintenance, featuring accessible components and clear documentation. This ensures that routine maintenance tasks can be performed efficiently.

8. Modular Design for Scalability:

The skid systems are designed with a modular approach, allowing for scalability. This modular design facilitates future expansions or modifications based on evolving operational needs.

9. Advanced Connectivity and Control:

Features such as multistream loading (max. 4 streams) on a single skid frame, autonomous systems with built-in pumps, skid-mounted control systems, and fiber optics connectivity to the control room enhance operational flexibility.

Cryogenic's Tanker Truck & Rail Wagon Loading Skid Systems provide a comprehensive solution, ensuring operational excellence, safety, and compliance with industry standards. Trust in our expertise to meet your unique loading and unloading requirements efficiently.