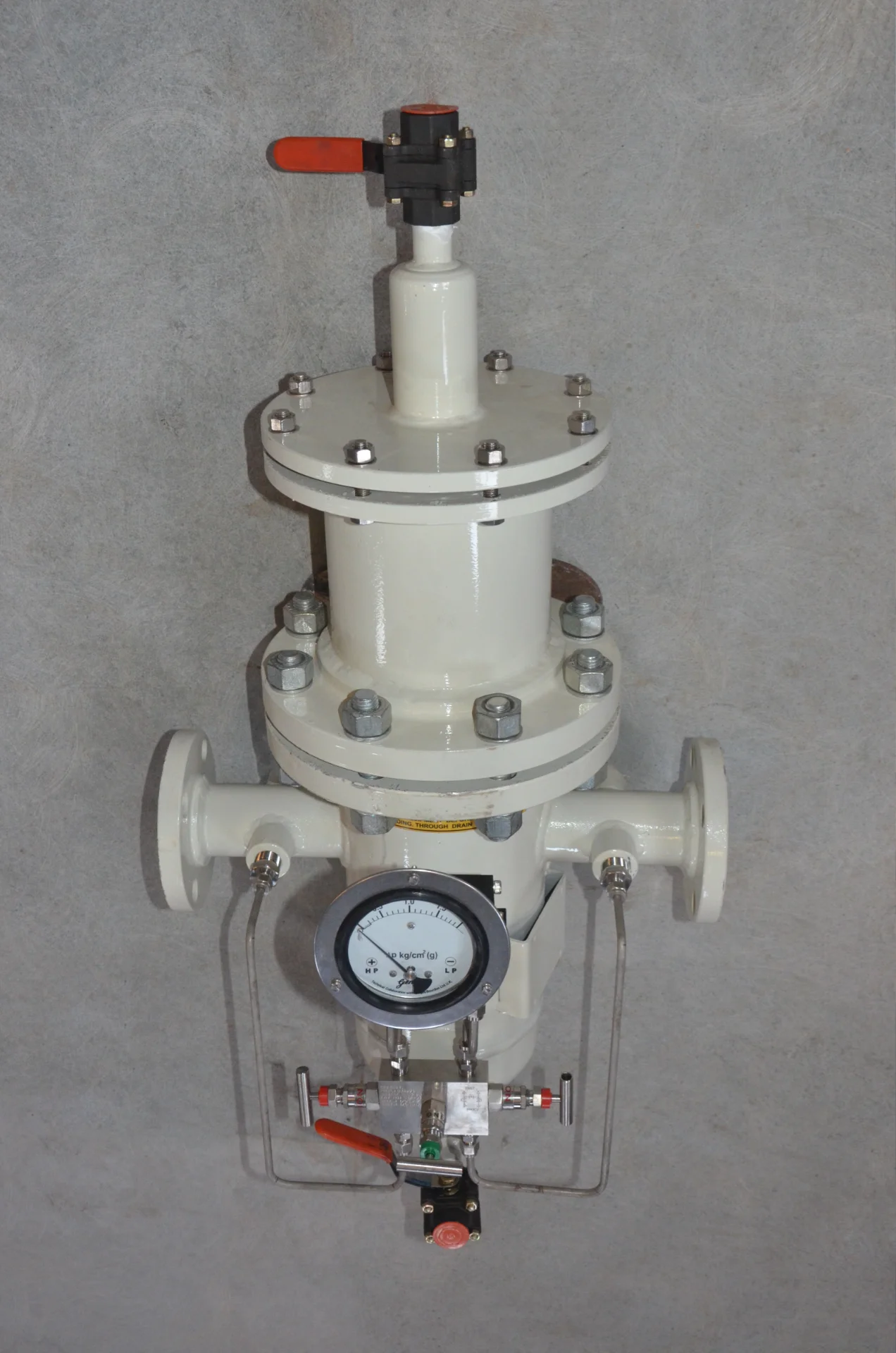

Introducing Cryogenic's Strainer cum Air Eliminator, a versatile solution meticulously engineered for a myriad of installations and conditions, specifically designed to address the simultaneous challenges of straining, filtering, and eliminating air/vapor from a diverse range of fluids.

1. Dual-Functionality for Straining and Air Elimination:

This innovative solution seamlessly integrates straining and air elimination functionalities, providing a comprehensive approach to fluid treatment.

2. Efficient Impurity Capture:

As unfiltered liquid enters the Strainer cum Air Eliminator, it traverses through a strategically placed basket, effectively trapping impurities and particulate matter, ensuring only clean liquid without air or vapor content exits through the outlet.

3. Advanced Dynamic Flow and Large Filtration Area:

Dynamic flow elements and an expansive filtration area contribute to low pressure drops, enhancing efficiency and reducing maintenance requirements for prolonged operational reliability.

4. Prevention of Bypassing:

The design incorporates an "O" Ring seal between the basket flange and the strainer internal flange, preventing any liquid bypass without filtration. This feature ensures a consistent and reliable filtration process.

5. Position Retention in Reverse Flow:

Even in the case of reverse flow, the Strainer cum Air Eliminator maintains the position of the basket, upholding its efficacy under varying flow conditions.

6. Space-Efficient Design for Gantry Considerations:

The combination of filtration and elimination in a single unit reduces space requirements, making it an ideal choice for Tank Truck Gantry and Tank Wagon Gantry designs.

7. Enhanced Accuracy of Measuring Devices:

Typically installed before measuring devices like Positive Displacement Meters, Turbine Meters, or Mass Flow Meters, the Strainer cum Air Eliminator enhances the accuracy of these measuring devices, ensuring reliable and precise readings.

8. Application Flexibility:

Ideal for scenarios where a significant portion of air is eliminated by a header Air Eliminator near storage tanks or pump houses, with the Strainer cum Air Eliminator efficiently handling the remaining air/vapor during tank or wagon loading.

9. Diverse Sizing Options and Special Configurations:

Available in sizes ranging from 1" to 24", accommodating flow rates up to 1800 m³/hr (30000 LPM) and designed to withstand pressures up to 100 bar. Cryogenic also offers duplex and jacketed types for specialized applications.

10. Proven Track Record:

With a commendable track record, Cryogenic has supplied over 3000 units by 2018, attesting to the reliability and trustworthiness of our Strainer cum Air Eliminators.

Experience unparalleled efficiency and reliability in fluid treatment with Cryogenic's Strainer cum Air Eliminator, where cutting-edge design meets proven performance. Elevate your fluid handling processes with this advanced solution tailored for diverse industrial applications.

| T - Type of strainer |

|---|

| T1 Simplex with top body flange |

| T2 Simplex with top body cover with Davit arm |

| T3 Simplex with Quick opening closure |

| T4 Simplex with jacketed |

| T5 Duplex with body flange |

| Nominal Size mm | ||||

|---|---|---|---|---|

| S0- 1" ( 25 mm) | S1 - 1.5" (40 mm) | S2 - 2" (50 mm) | S3 - 3" (100 mm) | S4 - 4" (100 mm) |

| S5 - 6" (150 mm) | S6 - 8" (200 mm) | S7 - 10" (250 mm) | S8 - 12" (300 mm) | S9 - 14" (350 mm) |

| S10 - 16" (400 mm) | S11 - 18" (450 mm) | S12 - 20" (500 mm) | S13 - 24" (600 mm) | S14- As per customer's requirment |

| R - Rating (Standard flange are slip on race face type if Weld Neck type is required please specify) |

|---|

| R1 – ANSI B 16.5 150# |

| R2 – ANSI B 16.5 300# |

| R3 - ANSI B 16.5 600# |

| M - Material of construction |

|---|

| M1 SA 516 Gr.70 (Body) & ASTM A 105 (Flanges) |

| M2 SA 516 Gr.70 (Body) & SA 350 LF2 (Flanges) |

| M3 IS 2062 Gr.B (Body) & ASTM A 105 (Flanges) |

| M4 SS 304 (Body) & ASTM A 182 F 304 (Flanges) |

| M5 SS 316 (Body) & ASTM A 182 F 316 ( Flanges) |

| M6 SA 106 Gr.B (Body) & ASTM A 105 ( Flanges) |

| M7 SA 333 Gr.6 (Body) & SA 350 LF2 ( Flanges) |

| * NOTE : All gaskets/Seals will be CS inner /outer with PTFE/Graphite filler and stud /nuts will be ASTM A 193 Gr.B7 / A 194 Gr.2H |

| For Stainless Steel and Low temperature service Gasket and Fastners are different |

| B - Basket and Mesh size |

|---|

| B0 Basket with SS 316- 200 mesh |

| B1 Basket with SS 316 - 100 mesh |

| B2 Basket with SS 316 - 80 mesh |

| B3 Basket with SS 316 - 60 mesh |

| B4 Basket with SS 316 - 40 mesh |

| B5 Basket with SS 316 - 20 mesh |

| B6 Customized basket with wire mesh size |

| F - Flow range (It Can be any between Specified Value) | |||

|---|---|---|---|

| F0 0 - 500 LPM | F1 0 - 1000 LPM | F2 0 - 1500 LPM | F3 0 - 2500 LPM |

| F4 0 - 3600 LPM | F5 0 - 4800 LPM | F6 0 - 6000 LPM | F7 0 - 500 LPM |

| F8 0 - 1000 LPM | F9 0 - 1500 LPM | F10 - 0 to Customer Specific Flow rate | |

| P - Operating pressure (normal) |

|---|

| P1 0 to 6 KG/CM2 |

| P2 0 to 10 KG/CM2 |

| P3 0 to 15 KG/CM2 |

| P4 0 to 25 KG/CM2 |

| P5 0 to 50 KG/CM2 |

| P6 0 to 75 KG/CM2 |

| P7 0 to 100 KG/CM2 |

| Accessories |

|---|

| A1 Ball valve for drain and vent |

| A2 Differential pressure gauge with manifold & tubing |

| A3 Differential pressure transmitter with manifold and tubing |

| A4 Differential pressure gauge with reed switch ,manifold and tubing |

| A5 Differential pressure gauge with diaphragm seal |

| A6 Thermal Safety Valve |

| If you want to order all above items kindly insert as A123456 |